Precision 3D Scanning Services in Perth: Transforming Engineering and Fabrication

In industries where precision isn't just preferred but essential, 3D scanning technology has become an indispensable tool for engineers, designers, and fabricators. At Composite Components in Perth, Western Australia, our EinScan HX handheld scanner is helping clients across defence, mining, maritime, aerospace, construction, UAV, and arts sectors create accurate digital models of existing objects, opening new possibilities for innovation, preservation, and problem-solving.

Why use 3D Scanning services?

Traditional measurement methods, while useful, have limitations when dealing with complex geometries, organic shapes, or components in hard-to-reach locations. 3D scanning captures millions of data points in minutes, creating a complete digital replica of an object with sub-millimetre accuracy. This precision matters when you're reverse-engineering a discontinued part, documenting heritage equipment, or ensuring perfect fit for composite repairs.

The EinScan HX uses both blue laser and LED hybrid light sources, allowing it to scan a wide range of materials and surface finishes, from reflective metals to matte composites, without the need for coating or powder application in most cases.

Real-World Applications of 3D Scanning Across Industries

Defence and Aerospace

When legacy components fail and original CAD files don't exist, 3D scanning enables rapid reverse engineering. Equipment, aircraft components, and UAV parts can be scanned, analysed, and moulds can be made to make duplicate parts.

Mining and Heavy Industry

Mining equipment operates in harsh conditions where wear and failure are inevitable. Scanning worn parts allows engineers to identify failure patterns, optimise designs, and manufacture replacement components locally rather than waiting months for international suppliers. This minimises downtime and reduces costs significantly.

Maritime

Boat builders and marine engineers use 3D scanning for hull modifications, custom fitting of equipment, and creating moulds for composite repairs. The technology excels at capturing compound curves and complex geometries typical in marine applications.

Architectural Construction

From heritage building documentation to quality control verification, 3D scanning ensures that prefabricated components will fit precisely in the field. It's particularly valuable when working with existing structures where "as-built" conditions differ from original plans.

Arts and Cultural Heritage

Public art collections, museums, and artists benefit from digital preservation of unique pieces. Scans provide permanent records for insurance purposes, enable accurate restoration if damage occurs, and can be used to create authorised reproductions or scale models.

The Engineering Workflow: How 3D Scanning Integrates

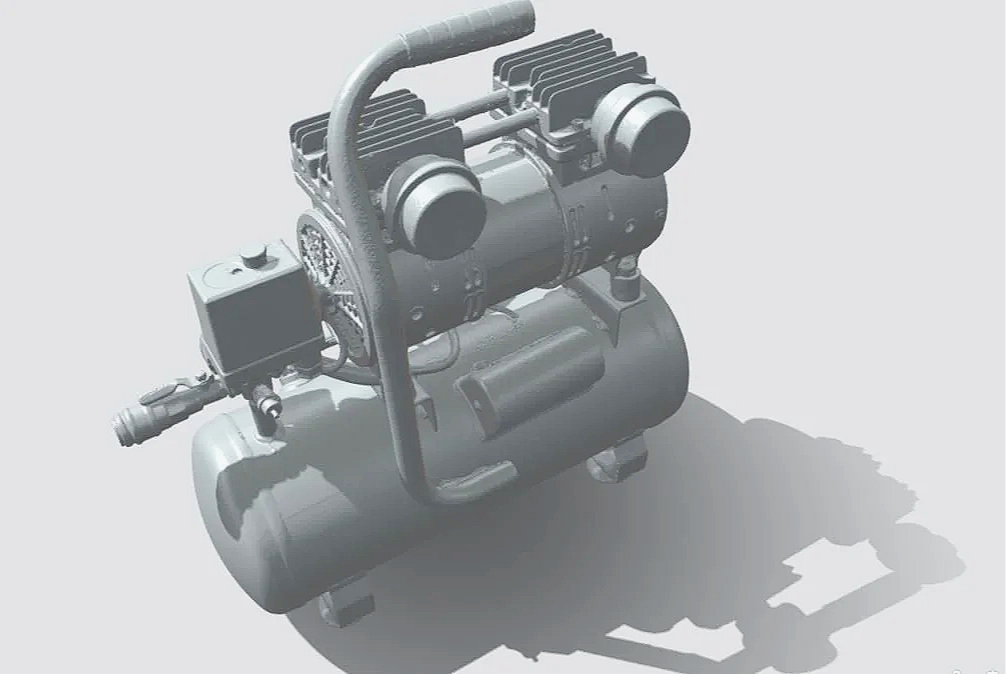

The process begins with either scanning the object at our Perth facility or visiting the site of the object if needed. The handheld nature of the 3D scanner means we can capture components of various sizes and access difficult angles without requiring specialised tools. The scanner collects point cloud data that's then processed into a mesh model.

Engineers receive formats compatible with standard CAD software (STL, OBJ, or converted to STEP/IGES), allowing immediate integration into design workflows. From there, the model can be used for dimensional analysis, reverse engineering, finite element analysis (FEA), or direct manufacturing via CNC machining.

For composite fabrication specifically, scanned data informs mould design, ensures proper clearances for assemblies, and validates that replacement parts will integrate seamlessly with existing systems.

3D model generated from a 3D scan of a compressor

When to Choose 3D Scanning Over Traditional Methods

Consider 3D scanning when:

Original drawings or CAD files are unavailable

The geometry is too complex for manual measurement

You need to capture an object in its current condition (including wear or deformation)

Time constraints make traditional measurement impractical

You're documenting something for future reference or replication

Precise fitment with existing components is critical

Proven Results: How We Use 3D Scanning In-House

At Composite Components, we don't just offer 3D scanning as a service, we rely on it daily in our own fabrication processes. Recently, we used the EinScan HX to accurately model existing heavy vehicle structures where our new composite parts needed to integrate. By capturing the precise geometry of mounting points, attachment interfaces, and surrounding components, we ensured a perfect fit before manufacturing even began.

We've also integrated 3D scanning into our quality control workflow. After manufacturing complex parts, we scan the finished component and compare it digitally against the original CAD design. This verification process catches any deviations before shipping, giving our clients confidence that what arrives on site will fit exactly as specified, eliminating costly rework and installation delays.

Why Work with Composite Components?

Our expertise in composite fabrication- working in a range of materials from carbon fibre, fibreglass, timber, metals and plastic- combined with our engineering team means we don't just provide scanning services. We understand how the data will be used in fabrication and can advise on the best approach for your specific application. Whether you're local to Henderson’s Maritime precinct, Kwinana's industrial precinct, north in the Pilbara's mining operations, or anywhere across Western Australia, we're equipped to help you transition from physical object to digital model to manufactured solution.

The combination of advanced scanning technology and deep materials knowledge, whilst also being a small agile business, sets us apart. We speak the language of engineers and understand the demands of industries and can respond quickly.

Get Started

If you have a component that needs reverse engineering, documentation, or replication, 3D scanning could be the solution. Contact Composite Components to discuss your project and discover how precision digital capture can solve your engineering challenges.