Why Composite Materials Testing Matters for Critical Engineering Projects

When your project depends on composite structures performing under extreme conditions; whether that's a naval vessel component facing saltwater corrosion, mining equipment enduring constant vibration, or a UAV structure requiring precise strength-to-weight ratios, how do you know your design will actually work?

The answer lies in materials testing, and it's become significantly more accessible for Western Australian engineers with Composite Components' recent acquisition of a 100 kN Universal Testing Machine at our Perth facility.

The Gap Between Theory and Reality

Composite materials are remarkable for their customisable properties. Unlike metals with well-documented performance characteristics, each composite laminate behaves differently depending on fibre type, resin system, lay-up sequence, manufacturing method, and even environmental conditions during fabrication.

This variability creates a challenge: design handbook values are conservative by necessity, often resulting in over-engineered structures that add unnecessary weight and cost. Finite element analysis provides insights, but simulations are only as accurate as the material properties you input.

Materials testing bridges this gap between theoretical performance and real-world behaviour.

When Does Testing Becomes Essential?

Several scenarios make composite testing not just valuable, but critical.

Material qualification

Material qualification ensures that new fibre-resin combinations or manufacturing processes actually deliver the performance you're counting on. Before committing to full-scale production of a composite component for a mining conveyor system or defence application, testing validates that your material choices meet specification.

Design allowable development

Design allowable development replaces conservative handbook estimates with actual performance data from your specific material system. This is particularly important for weight-critical applications in aerospace and UAV projects, where every gram matters. Real test data often reveals you can use thinner laminates than handbook values suggest, reducing both weight and material costs.

Complex joint testing

Joints are often complex and at high risk of failure. Complex joint testing addresses situations that are difficult or impossible to model accurately through FEA alone. Adhesive bonds, bolted joints in composites, insert pull-out strength, and multi-material interfaces all benefit from empirical testing. For maritime and offshore applications where joint failure could be catastrophic, this data is invaluable.

Quality assurance programs

Quality assurance programs use regular coupon testing to verify that your material supply chain and manufacturing processes remain consistent over time. This is standard practice in aerospace but increasingly important in other industries as composite use grows.

The Engineering Advantage of Materials Testing

What distinguishes valuable materials testing from simply generating data points, is the engineering insight behind it.

At Composite Components, testing is conducted by the same composite engineers who design and manufacture advanced structures for clients including BHP, Rio Tinto, Fortescue, Thales, and BAE Systems.

This means test results come with interpretation. When a sample fails at a particular load, our engineers can explain why, suggest design modifications, and help you understand whether the failure mode matters for your specific application. For a structural engineer designing a composite platform component, this context is often more valuable than the raw numbers.

The integration of testing with our finite element analysis and manufacturing capabilities creates a particularly powerful workflow. Engineers can simulate a design, validate the simulation with tested material properties, refine the design based on actual performance data, and then manufacture the optimised component, all within our organisation.

Local Access, National Capability

For Western Australian companies, having composite testing available locally in Perth eliminates the logistical challenges of interstate shipping. Delicate test samples don't risk damage in transit, turnaround times shrink from weeks to days, and direct consultation with testing engineers becomes straightforward.

Our standard turnaround is two weeks from sample receipt to comprehensive reporting. For companies across Australia, composite test samples are typically compact enough for express courier shipping, making our capabilities accessible nationally, while offering particular advantages to local clients.

Current Testing Capabilities

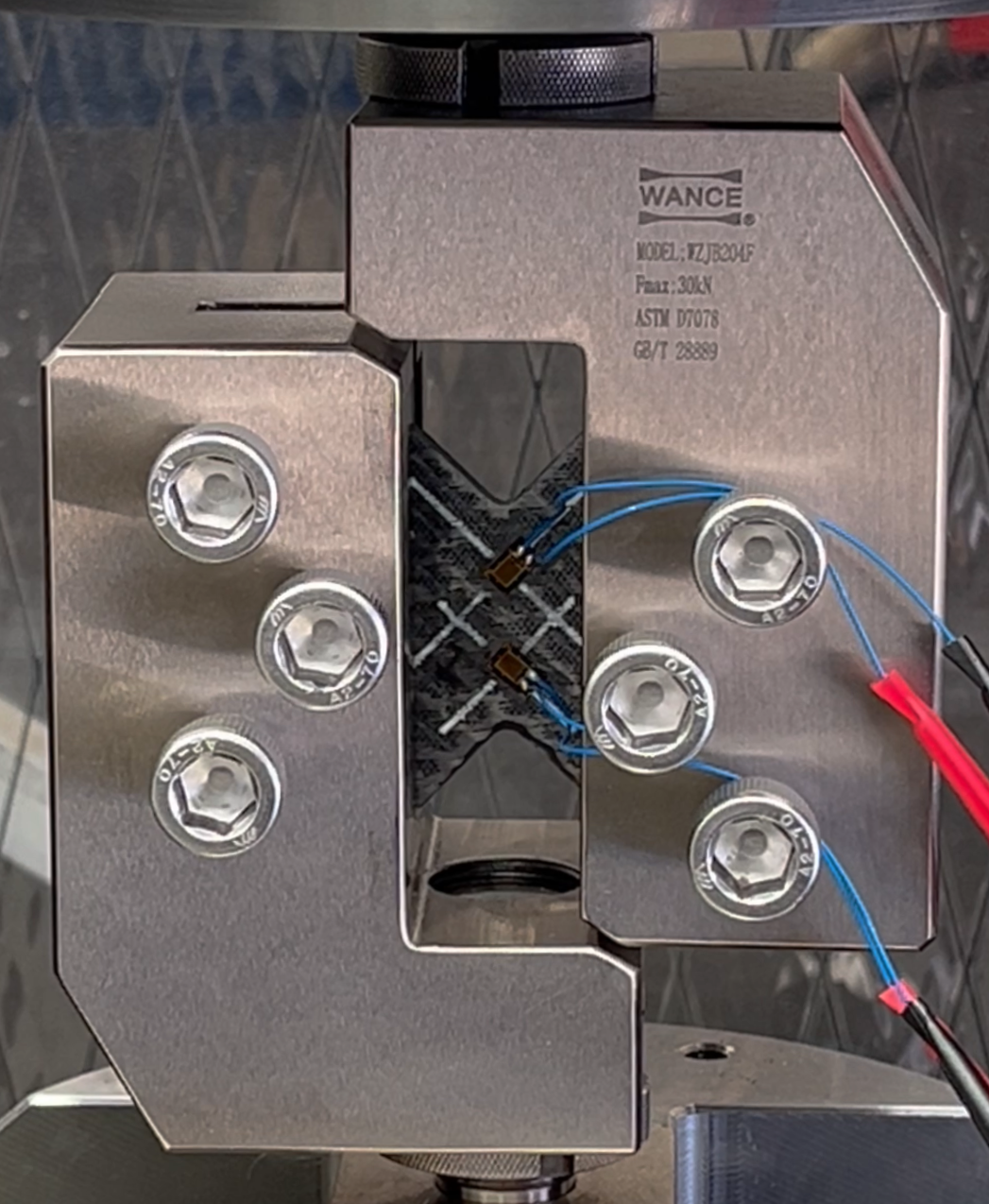

Our 2025-manufactured Universal Testing Machine provides 100 kN capacity in both tension and compression, with 1100 mm testing height accommodating most composite panel and component geometries. We currently maintain tooling for standard ASTM test methods including tension testing, v-notched shear, combined compression, four-point bending, and single lap-joint adhesive shear strength.

Beyond standard tests, we specialise in custom testing solutions. If your component has an unusual geometry, requires a non-standard load case, or needs specialised fixturing, our engineering team can design and fabricate the necessary tooling. This flexibility has proven essential for clients with unique testing requirements that commercial labs struggle to accommodate.

V-notch shear testing of a carbon fibre part, with strain guages attached.

Making Testing Work for Your Project

The key to valuable materials testing is knowing what questions you're trying to answer. Are you validating a new material supplier? Optimising laminate thickness? Qualifying an adhesive for a critical joint? Understanding why a component failed in service?

Each objective requires a different testing approach, and our initial consultation process helps define the right test protocol for your specific needs. Testing for the sake of testing wastes resources. Testing to answer specific engineering questions drives better designs and more confident decision-making.

For industries where composite failure carries serious consequences, such as offshore platforms, naval vessels, mining equipment, load-bearing structures, the investment in materials testing is a fraction of the cost of failure. For weight-critical applications in aerospace and UAV development, testing often reveals optimisation opportunities that pay for themselves in material savings.

Looking Ahead

We're currently pursuing NATA accreditation to provide formally certified testing services, which will further support clients requiring traceable, auditable test data for regulatory compliance or quality management systems.

As composite materials continue to replace metals across industries, the need for reliable, engineer-led materials testing grows. Whether you're developing a next-generation UAV, qualifying materials for a defence contract, optimising a mining equipment design, or investigating a field failure, understanding how your composites actually perform under load often isn't optional, it's necessary.

Ready to validate a composite design with real data?

Contact Composite Components to discuss your testing requirements and discover how materials testing can strengthen your engineering decisions.